HBI hosts UQ Engineering student for the development of Custom Photogrammetry Equipment for Design, Manufacturing and Quality Assurance of Personalised Medical Devices.

Name: Peter Storeshaw

Project Title: Custom Photogrammetry Equipment for Design, Manufacturing and Quality Assurance of Personalised Medical Devices.

Supervisor: Dr David Forrestal

I spent six months at HBI as part of my Masters industrial placement. As an electrical and biomedical engineering student I was excited to use and improve my skills on a real-world project that could affect the care of patients in the future.

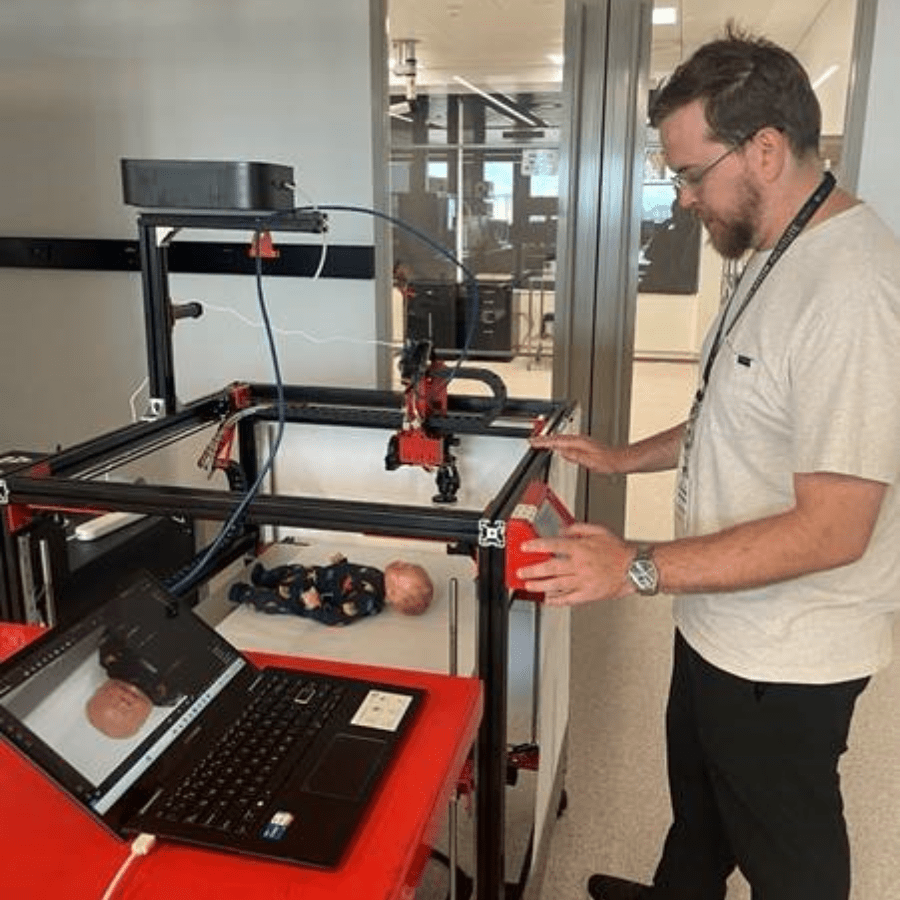

The project involved the design and implementation of a modular photogrammetry rig tailored for biomedical applications, to assist HBI in capturing and producing accurate 3D models. Current methods have significant limitations when used for certain applications. The device was designed for easy modification and manipulation, allowing for rapid adaptation to various medical applications where current methods are not sufficient.

The device consists of a number of Raspberry Pi’s that each control a camera and connect to a central computer. The system has been designed such that the number of Raspberry Pi’s is determined by the specific application and can be easily modified. A GUI was developed to control the capture of images, image processing and collection of images from each camera. The image set can then be inspected and used by one of two chosen photogrammetry programs to produce 3D models with removable texture files.

The system was developed and tested using a 3D printer as a platform, enabling the testing of cameras in any orientation and quantity within the printer’s workspace. Camera number, camera quality, lighting, image orientation, photogrammetry program, camera settings and depth cameras were all investigated or tested using this platform. The system produces 3D models that have a deviation of less than 0.3mm from the initial computer model, in less than ten minutes, with 24 cameras, which is much better than initial requirements.

My experience with HBI was very rewarding. I have gained invaluable insight into the design and development of biomedical devices, including ensuring compliance with medical standards and regulations. Furthermore, the exposure to HBIs printing lab has improved my knowledge of 3D printing technology. Being in control of the scope, and development of the project has also seen my project management, communication, research and programming skills improve beyond the levels of what a standard university course provides. All of which will aid greatly in my future engineering career.

I would like to thank all the team members of HBI who were always available to help and whose insights were vital to the end product.